- You have no items in your shopping cart

- Continue Shopping

Description

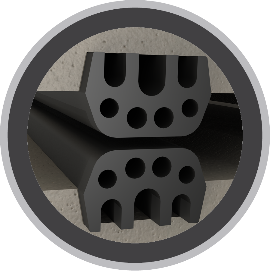

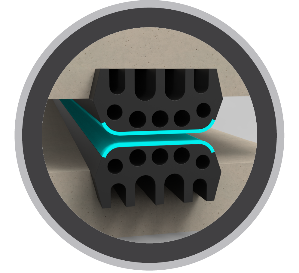

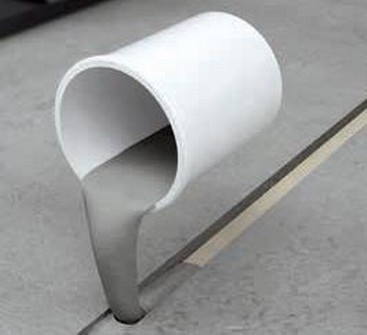

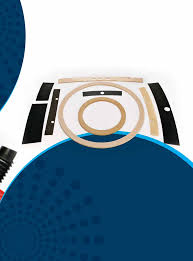

Cast-in gaskets (also known as anchored gaskets or cast in situ gaskets) are integrated with the segment during the casting process.

This is opposed to being glued into a pre-made groove once the concrete segments have been cast.

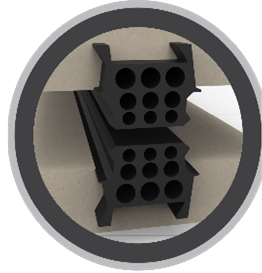

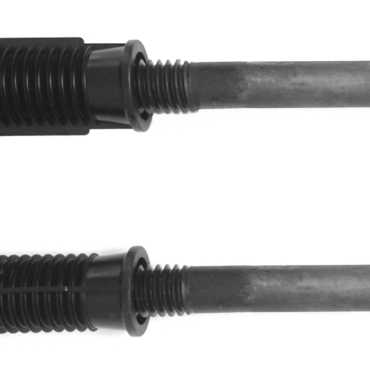

Cast-in sales ‘anchor’ themselves to the segment as the concrete surrounds the legs at the base of the seal.

This process ensures a consistent positioning of the gasket around the segment.

The design of the legs ensures that the seal is secure in the segment and will not move duing or after the segment is cast.

This is especially important during installation of the tunnel segments.

BENEFITS OF THE CAST-IN GASKETS

- No need to apply adhesive

- Cleaner to work with

- Provide cost savings due to the removal of the adhesive and the gluing process

- A more secure fit in the segment leading to reduced movement of the seal during installation and increased performance

Dimensions

Details TDS size & shape will submit upon request