- You have no items in your shopping cart

- Continue Shopping

Description

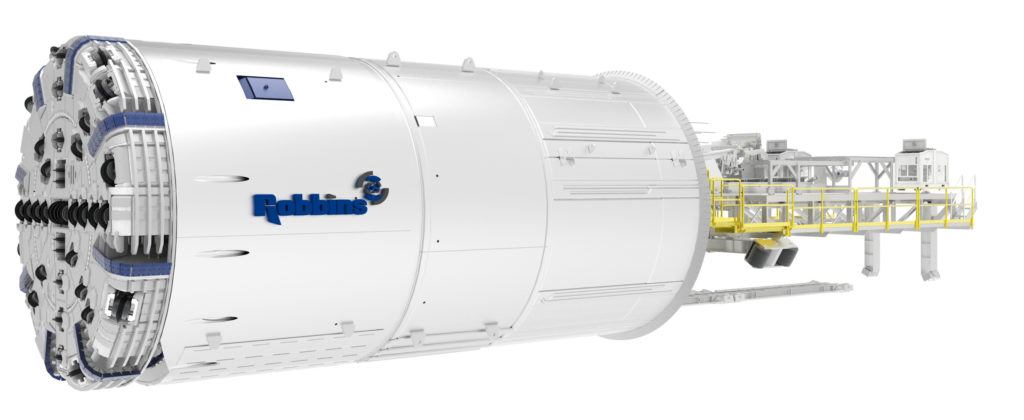

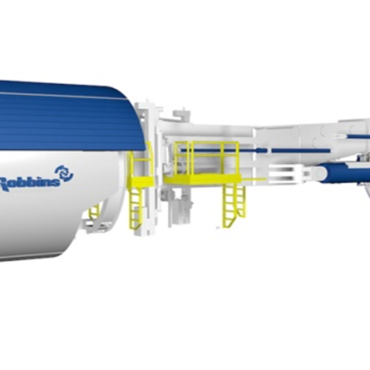

Robbins Single Shield TBMs protect workers from broken rock until the tunnel lining can be safely installed. The body of the machine is enclosed in a shield that is marginally smaller than the diameter of the tunnel. The flat, low-profile cutterhead minimizes disturbance of the face as it bores, and prevents large blocks from collapsing and causing excessive boring stresses. The front of the TBM is a rotating cutterhead that matches the diameter of the tunnel. As the cutterhead turns, a ring of hydraulic cylinders provides forward thrust through shoes that push against the tunnel lining. The cutterhead holds disc cutters (ranging from 11″ to 20″ in diameter) positioned for optimal boring. The transfer of high thrust through the rolling disc cutters creates fractures in the rock, causing chips to break away from the face. Boring and lining installation are performed sequentially. To steer, cylinders orient the articulated cutterhead in the required direction.

Robbins Single Shield TBMs are available in diameters from 1.6 to 15 m (5 to 50 ft). All Single Shields are equipped with high-speed segment erectors for rapid tunnel lining installation. To steer the machine, the cutterhead is articulated. The short shield length enables a small turning radius and minimizes exposure to squeezing ground forces that could potentially trap the machine. Robbins Single Shield TBMs are designed with maximum equipment life in mind. Every machine is rated for 10,000 hours of excavation.